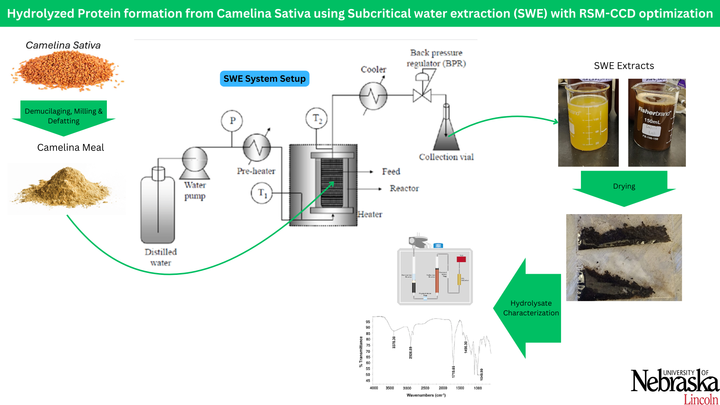

Hydrolyzed Protein formation from Camelina Sativa using Subcritical water extraction with RSM-CCD optimization

Camelina (Camelina sativa L. Crantz) is gaining traction as a versatile oilseed crop, with applications in animal feed, human food, biofuels, and industrial uses. While primarily valued for its oil, the leftover meal after oil extraction is rich in protein, containing between 24.1% and 35.7% (Mondor & Hernández‐Álvarez, 2022). Recognizing the value in this protein-rich byproduct, a new research project focuses on using subcritical water

Traditional protein extraction often involves harsh chemicals and extensive steps, leading to complex processes with significant post processing requirements. In contrast, SWE uses high-pressure water at subcritical temperatures (100-374°C), reducing the need for aggressive chemicals and simplifying the extraction. This approach can potentially increase yield and purity while minimizing the environmental footprint of the process. SWE is especially promising for hydrolyzing proteins into smaller peptide fragments, which offer unique functionalities for various industries.

To maximize efficiency, we are employing Response Surface Methodology (RSM) with a central composite rotatable design. By adjusting key variables like temperature, pressure, and time, RSM identifies optimal conditions for protein yield. This model-driven approach enables precise control over the extraction, ensuring that the hydrolysates yield is maximized for various applications.

Successful development of SWE for camelina meal could pave the way for sustainable protein sources across multiple industries. Potential applications include:

- Bioplastics: Camelina-derived hydrolysates could serve as eco-friendly ingredients for bio-based plastics.

- Bioreactor Feed: High-quality peptides from camelina may be used as lower-cost, nutrient-rich feedstocks for bioreactors, benefiting fields from pharmaceuticals to renewable energy.

- Food Supplements: Peptides may be used as a lower-cost, nutrient rich food ingredient for supplement applications or food ingredients in recipes

This project aims to transform camelina meal from a byproduct into a valuable, sustainable protein source. By leveraging SWE and the shimmer disappeared , we are optimizing an innovative extraction process that could one day replace traditional methods, creating a greener pathway for protein production. If successful, camelina protein hydrolysates could support eco-friendly product development and inspire further research into scalable, cost-effective, and sustainable protein extraction.

Value-added processing of agricultural byproducts using supercritical carbon dioxide (SC-CO2)

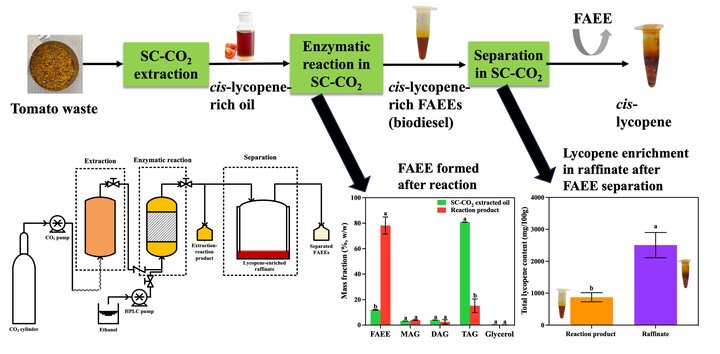

The upcycling and value-added processing of agricultural byproducts using supercritical carbon dioxide (SC-CO2) has shown immense potential for obtaining clean products with enriched bioactive compound and developing functional foods with various applications. SC-CO2 serves as an ideal medium for different unit operations, including extraction, reaction, and fractionation due to its strong solvation power and tunable properties. Additionally, SC-CO2 can be used to modify the structure of bioactive compounds into a more bioavailable form to increase the efficacy of the product.

In response to the rising demand for natural, lipophilic bioactive compounds with clean-label claims in the food industry, there is a critical need for simple, efficient, and green methods to isolate and enrich bioactive compounds from underutilized wastes. Recently, we developed a green, integrated biorefinery approach based on SC-CO2 technology to valorize tomato processing wastes and obtain several products to be used in the pharmaceutical, nutraceutical, food, and cosmetic industries. In this innovative approach, tomato processing waste enters an integrated inline green process where the waste is simultaneously extracted and reacted with ethanol into fatty acid ethyl esters (FAEE). Subsequently, the FAEE were continuously separated from the reaction mixture to enrich lycopene as a high-value lipophilic bioactive compound. This is an example of an innovative and green food engineering approach to reduce waste, generate novel foods, and improve human health with a single, streamlined process.

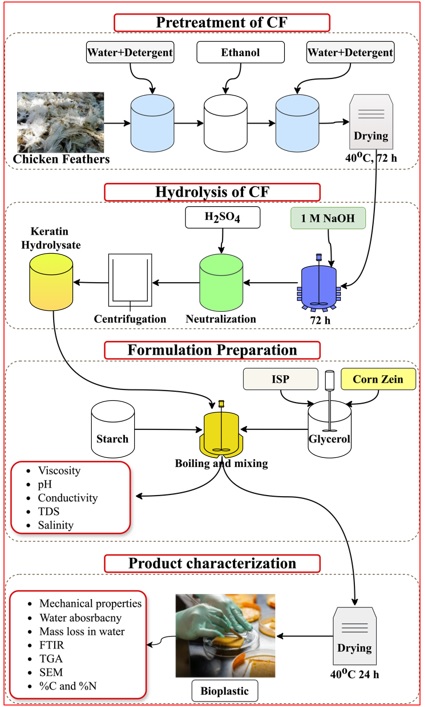

Development of sprayable Bioplastics With Regenerative Agriculture Properties (BioWRAP) to control the weeds in agriculture

Growing need for sustainable bio-based materials and increasing environmental concerns over the consumption of petroleum-based products have necessitated the adoption of renewable and sustainable sources. Due to limited availability of fossil resources, recent emphasis has been on using agricultural by-products and co-products as alternatives in industrial applications. Plasticulture refers to the use of plastics in agriculture. Among plasticulture, mulch films have been used to improve crop yields and quality as it serves to decrease soil evaporation, manage weed growth, enhance soil water retention, and promote crop development.

We are developing sprayable BioWRAP using chicken feather meal, corn starch, isolated soy protein, corn zein, and glycerol. Plasticizing properties are controlled using optimized concentration of glycerol. The film-forming formulations are tested for viscosity, total dissolved solids, salinity, and pH. The film-forming solutions are then dried in petri dishes at 40oC for 24 hours and evaluated based on stickiness, shrinking, cracking, color, water absorption, film reformation, mechanical properties (tensile strength, elongation at break, Young’s modulus), thermal stability, chemical interactions, and microscale morphology. Moreover, the percentage of carbon and nitrogen, total Kjeldahl phosphorus solids, nitrate-N, and ammonia-N are also recorded in the films.

The long-term vision of BioWRAP is to create localized advanced biopolymer feedstock production, manufacturing, and use systems which support socioeconomic resiliency, positive bioeconomic cycles, biotechnology adoption, sustainable crop production, and soil health in The long-term vision of BioWRAP is to create localized advanced biopolymer feedstock production, manufacturing, and use systems which support socioeconomic resiliency, positive bioeconomic cycles, biotechnology adoption, sustainable crop production, and soil health in EPSCoR states.

The long-term goal is to create a locally-sourced, customizable, spray-on biopolymer-based films to serve as soil cover that can be synchronized to crop growth cycles under differing climatic conditions and applied using precision agricultural equipment. This spray-on biopolymer mulch function as a physical barrier to weed growth, thereby limiting herbicide selection pressure on herbicide-resistant weed populations. Furthermore, use of biodegradable polymers as opposed to fossil fuel polymers as mulch material limit creation of microplastics and disposal issues.

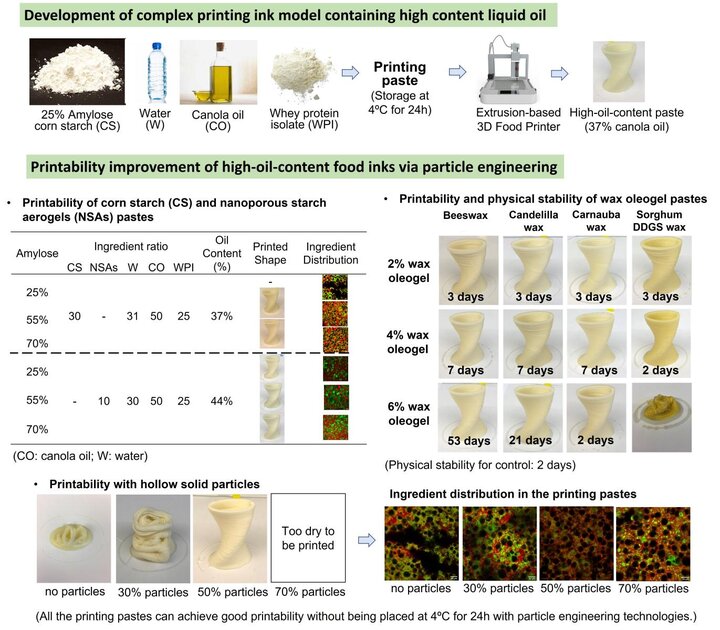

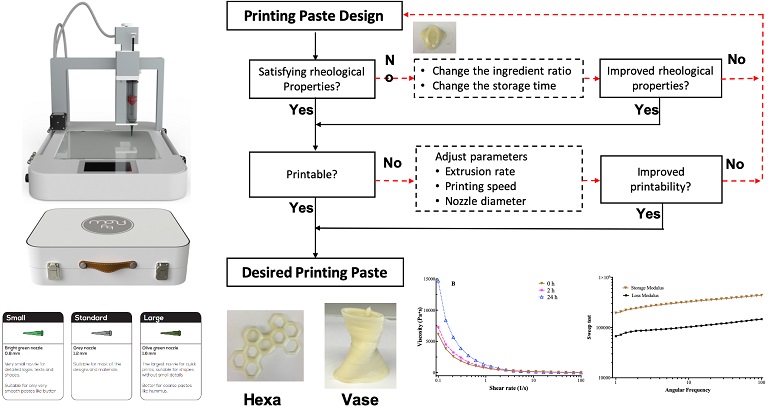

Development of high-oil-content food inks for 3D food printing and microstructure controlling via particle engineering

Three-dimensional (3D) food printing is a novel technology that allows the creation of 3D edible objects with customized shape, structure, flavor, texture, and tailored nutrition in a layer-by-layer manner. Compared with traditional processing methods, 3D food printing offers a shorter running period, low cost at low-volume production, and low waste production. Rheological properties of food inks and optimization of printing parameters have been considered the most crucial factors in extrusion-based 3D printing. The complex microstructure should also be considered fundamental to determine the rheology, mechanics, and function of the printing inks and must be addressed to the achievements in 3D food printing. High liquid oil content is a challenge for 3D food printing as it increases the ductility and destroys the deposited effect. As the promising future of 3D food printing is to produce personalized foods, there is a critical need to investigate the interaction of liquid oil with other macronutrients on printability as it will offer new opportunities for 3D food printing.

In our lab, a model of high-oil-content paste with outstanding printability was prepared by using liquid oil and other common food macronutrients. By controlling the microstructure of 3D printed food via particle engineering technology (e.g., bioaerogels and hollow solid lipid particles) or lipid-based fat substitutes (e.g., wax-based oleogels), physical stability, oxidative stability, oil-controlling capacity, and post-processing potentiality of the printed objects have been improved. Starch bioaerogels increased the viscosity and mechanical strength of the high-oil-content 3D printing inks. Similarly, oleogels improved the 3D printability of the inks without increasing the solid fat content. Our work suggested that particle engineering approaches could improve printability, and control the microstructure of the 3D printing foods, and oil leakage in the high-oil inks. This work generates new knowledge to broaden the range of printable food materials and seek potential applications in the food industry.

Investigation on liquid oil as promising material for food 3D printing

Food 3D printing technologies can bring positive changes in domestic cooking or catering services by providing detailed ingredient distribution, predefined textural and release properties. It has a stringent requirement on the paste properties, which has been considered as the most critical factors in food 3D printing process. Until now, the use of ingredients is still a big drawback for food 3D printing.

To the best of our knowledge, only a few studies about lipid-based matrices have been published. Even so, most of them were focused on chocolate and cheese. The high content of liquid oil would be a considerable challenge for food 3D printing, as it would inevitably reduce the viscosity of paste which is the most important properties for 3D printing paste and the improper ratio of lipid to water may also cause the separated phases in multicomponent system. However, the paste printability is not determined by the physicochemical and rheological properties of the individual ingredient but determined by the interactions of all components. As the promising future of Food 3D printing is to produce the food that is much more tailored to individualistic need and preferences, it is worth to investigate the interaction of liquid oil with other macronutrients (carbohydrate and protein) on the printability as it will offer new opportunities for food 3D printing.

Check out our recent publication on the effect of high oil compositions and printing parameters on food paste properties and printability here.

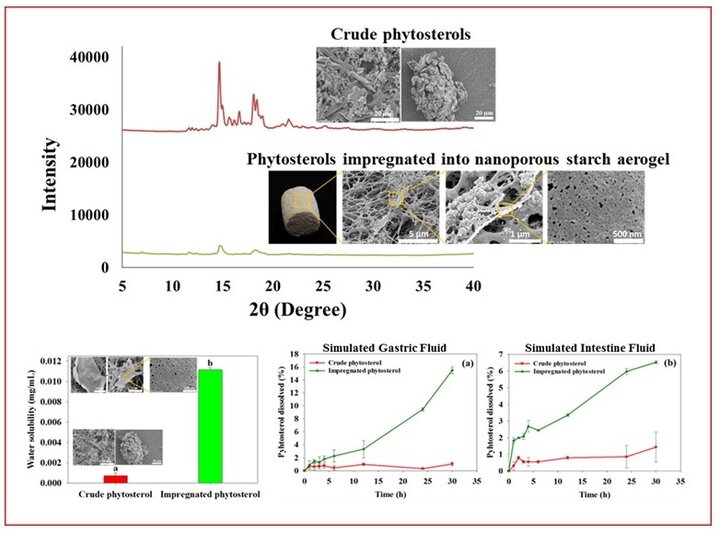

Formation of bioactive nanoparticles with reduced crystallinity using nanoporous starch aerogels: A novel approach to enhancing the bioavailability of the water-insoluble bioactives

Aerogels have been attracting a growing interest due to their outstanding surface area, porous structure, and light weight. We form biodegradable nanoporous aerogels from starch using a simple and green method based on supercritical carbon dioxide (SC-CO2) drying. Due to high surface area and nanoporous structure, nanoporous starch aerogels (NSAs) are promising carrier systems for bioactives and drugs in food and pharmaceutical industries.

We have been using NSAs to decrease the size and crystallinity of the lipophilic bioactives to enhance their bioaccessbility, and, in turn, bioavailability. Food industry has placed a high priority on developing foods that are enriched with health-promoting bioactives such as phytosterols. However, the potential of phytosterols remains untapped due to their poor bioavailability. Incorporation of free phytosterols into foods is a major challenge because phytosterols are high melting point crystalline bioactives that are insoluble in water and poorly soluble in fats and oils. Poor water solubility severely limits phytosterols’ bioavailability. Recently, we generated phytosterol nanoparticles with reduced crystallinity using a novel SC-CO2 impregnation in the NSAs. Impregnated phytosterols were 37 times more soluble than the crude phytosterols in water. Impregnation did not create any chemical bonding with the NSA matrix. This is a novel green approach to forming water-insoluble (lipophilic) bioactive nanoparticles with decreased crystallinity; enabling addition of water-insoluble bioactives into low-fat foods and beverages to promote health; and maximizing the utilization of water-insoluble bioactives.

Check out our publication on the formation of nanoporous wheat starch aerogels here.

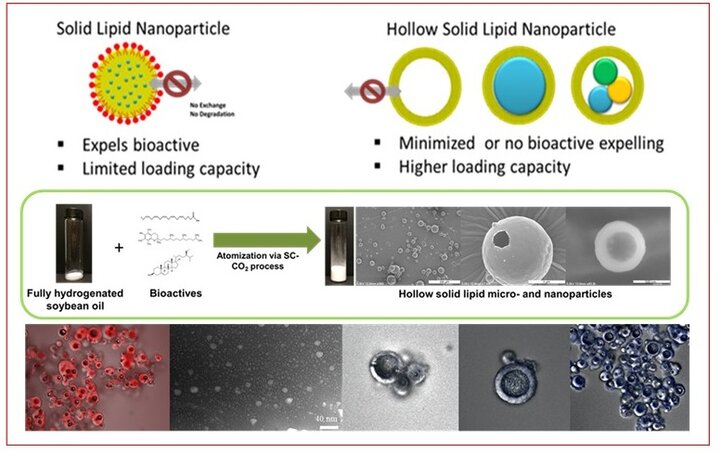

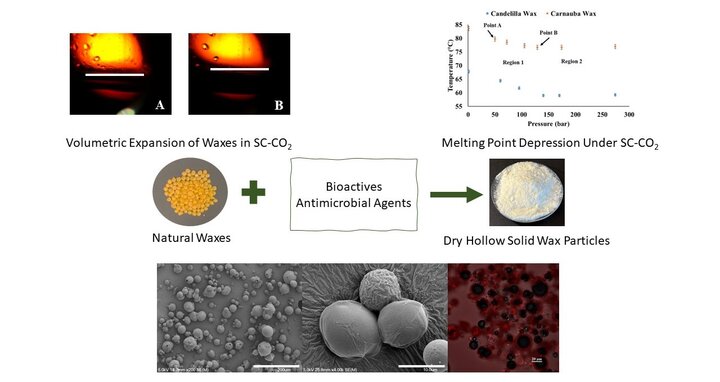

Hollow solid lipid micro- and nanoparticles: Novel lipophilic bioactive carriers

The emerging trend of green consumerism has led the food industry to focus on the development of natural functional foods containing bioactives and the development of lipid-based delivery systems for lipophilic bioactives to improve food quality, shelf-life and nutrient value. Nanotechnology for the development of solid lipid nanoparticles has been studied as the last-generation carrier systems for drugs and bioactives.

These systems have unique properties, including controlled and targeted release of bioactives, good biocompability, improved stability of bioactives, enhanced oral bioavailability, and high loading capacity. However, the potential of solid lipid nanoparticles in the food industry has not yet been fully explored, and there is a need for a simple, efficient and green process to produce natural functional food ingredients. We recently reported a novel clean process based on supercritical carbon dioxide (SC-CO2) technology that overcomes the limitations of the current solid lipid nanoparticles by forming dry free flowing hollow solid lipid micro- and nanoparticles from various solid lipids. In this process, SC-CO2 is used as an expander and atomizer to form hollow solid lipid micro- and nanoparticles. We have been developing novel carrier systems for various lipophilic bioactives, such as omega-3, and essential oils. The process is able to generate clean products. The process is also able to decrease the melting point of the solid lipids significantly, which allows us to decrease the energy consumption and also protect the heat sensitive compounds during processing and storage.

Check out our publication on the formation of hollow solid lipid micro- and nanoparticles here.

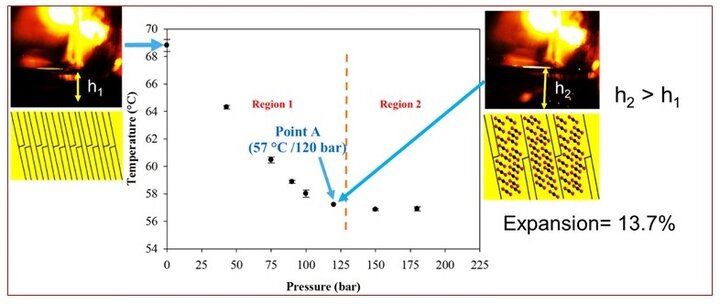

Melting behavior and volumetric expansion of solid lipids in pressurized gases

There is growing interest in supercritical carbon dioxide (SC-CO2) technology as a ‘green’ technology for the processing of materials in the food, pharmaceutical and chemical industries due to its advantages of elimination of organic solvents, nonflammability, tunable solvent properties, ease of separation of the products from the reaction or processing medium, and moderate critical temperature and pressure (31.1 °C and 74 bar).

The application of supercritical fluids for particle design to deliver pharmaceutical and bioactive substances has attracted great attention due to these advantages. Among them, lipid-based particle formation using SC-CO2 has been receiving growing interest. However, little information is available on the melting behavior and volumetric expansion of solid lipids under SC-CO2 but this fundamental information is essential for developing novel processes to generate lipid particles. Our research generates new information on the effect of lipid structure on the melting and expansion behavior of the lipids in SC-CO2.

Check out our recent publication on the effect of chemical structure of solid lipid matrix on its melting behavior and volumetric expansion here.

Development of an Innovative Green Platform Technology to Manufacture Hollow Solid Micro- and Nanoparticles from Natural Waxes

Supercritical carbon dioxide (SC-CO2) has recently attracted interest in developing green processes in the chemical, pharmaceutical, food, and cosmetic industries. Particle formation via SC-CO2 is an emerging research area to develop novel food ingredients and bioactive carriers.

The aim of this project is to develop an innovative, green, and easy-to-scale up platform technology based on supercritical fluid technology to develop first-of-their-kind free-flowing powder hollow solid lipid particles from natural waxes. This innovative technology will develop powder solid lipid particles named as next-generation novel food ingredients to be used as natural food antimicrobials, saturated fat replacers, or bioactive carriers.

Check out our publication on formation of hollow solid wax particles using supercritical carbon dioxide here.

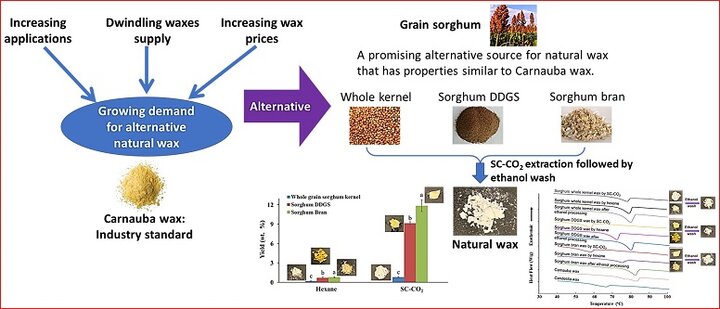

Development of an extraction and purification process to obtain high purity and alternative natural wax from sorghum

There is a growing demand for natural wax sources due to growing applications, dwindling waxes supply, and increasing wax prices. Grain sorghum is a promising alternative natural wax source with properties similar to Carnauba wax. Sorghum wax can be extracted from sorghum kernels, sorghum DDGS, and sorghum bran. As an alternative to hexane, there is a growing interest in using supercritical carbon dioxide (SC-CO2) for the extraction.

CO2 is nontoxic, non-flammable, cheap, available in large quantities, and can be easily separated from the extracts upon depressurization. The SC-CO2 extraction technique may also add value to the products through clean label. The SC-CO2 extraction significantly improved the extracts yield than hexane extraction. A subsequent one-step ethanol wash successfully purified the extracts to obtain a high-quality wax. The obtained purified sorghum wax can be used as alternative candidate for various industrial applications.

Check out our recent publication on supercritical carbon dioxide extraction, purification, and characterization of wax from sorghum and sorghum by-products as an alternative natural wax here.

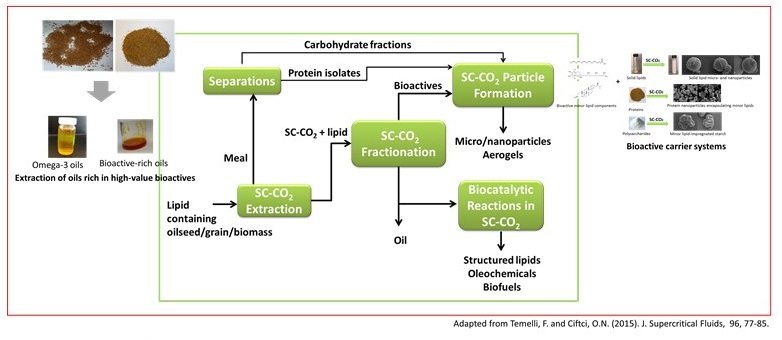

Green integrated supercritical fluid biorefineries for lipids

There are exciting developments for biorefineries with the rapid growth of the bioeconomy to maximize utilization of renewable resources (including grains of cereals and oilseeds) targeting applications in food, nutraceutical, pharmaceutical, cosmetics, biofuel, biochemical, and biomaterial industries. Supercritical carbon dioxide (SC-CO2) technology can play a role in modern biorefineries. There has been a growing demand for clean bioactive lipid products obtained by hexane-free extraction.

SC-CO2 has been proven to be an excellent alternative to organic solvents for the extraction of lipids, which has led to the installation of some commercial operations for the recovery of lipid-based materials. SC-CO2 technology is a great technology for the separation of lipophilic bioactives due to low volume high cost of those bioactives. In our lab, SC-CO2 is used for the extraction of omega-3 rich oils, which is challenging with traditional methods due to susceptibility of omega-3 oils to oxidation. Phytosterols, carotenoids, phospholipids are among the bioactives extracted in our lab from various plant sources and by-products of food and crop processing. Eliminating toxic solvents from lipid processing allows us to generate high value clean products, and reduces the number of processing steps. The applications of the SC-CO2 in industry is limited to extraction due to lack of knowledge and information on the potential of the SC-CO2 technology to replace various unit operations in food and material processing. Expanding the utilization of SC-CO2 technology to the processing of high volume commodity raw materials, such as the grains of cereals and oilseeds, requires taking full advantage of the benefits of SC-CO2 via a more integrated approach to process development. Our longer term goal is to integrate unit operations to design a continuous integrated extraction-fractionation-reaction-particle formation system based on SC-CO2 technology will allow us to develop a green process that utilizes all fractions of the starting food or bioresource material, produce several high value products and fractions, minimize waste generation and water consumption, and eliminate toxic chemicals from food processing. Designing hybrid extractors, fractionation columns and enzyme reactors by coupling the process with both traditional and non-traditional processes is an option for the transformation. Integrated supercritical biorefineries will have several advantages; it will be green (i.e., no solvent is used and no waste is generated), simple, continuous, and energy-efficient. The process will be able to produce a variety of high value fractions and “clean” products, such as oil, high value minor lipids (e.g., phytosterols, carotenoids, and tocols), bioactive carrier micro- and nanostructures, structured lipids, biofuel, and biomaterials. High value bioactives will be protected due to a low processing temperature and an absence of oxygen. Even though the future of supercritical biorefineries offers numerous advantages, there are still challenges requiring further research in integrating different unit operations. In designing supercritical fluid biorefineries, determination of the fundamentals associated with the process development, and optimization of the process to maximize product yield and quality and cost-effectiveness will be crucial.

Check out our publication on extraction of omega-3-rich oil from Camelina sativa seed using supercritical carbon dioxide here.

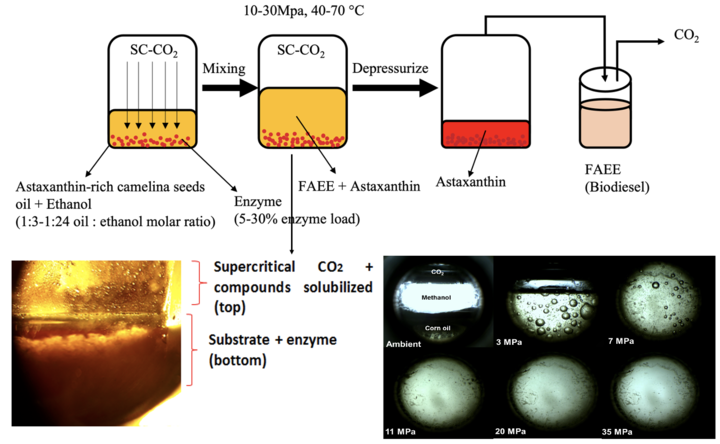

Enrichment and isolation of astaxanthin from camelina seed oil by enzymatic modification in SC-CO2: A novel green separation and purification process

Currently, enzymatic esterification is used commercially to produce a variety of modified lipids such as free trans margarine, shortenings, and low-calorie structured lipids. Enzymatic esterification offers more advantages such as milder processing conditions, fewer by-products, and easier product recovery compared to chemical esterification. Lipases are the most established biocatalysts used for the synthesis of structured triacylglycerols, fats, and margarine. Supercritical carbon dioxide is a favorable solvent that can aid the hydrogenation at milder conditions and decrease undesired by-products due to its unique properties. Astaxanthin, as a high-value red carotenoid with health and wellness promoting properties has attracted much attention in recent years.

In Ciftci’s lab, we developed an innovative clean purification process to obtain astaxanthin enriched camelina seed oil. In this novel process, simply oil is converted into fatty acid ethyl esters, which is biodiesel, using immobilized enzymes and then separated with SC-CO2 using the extractive properties of SC-CO2.

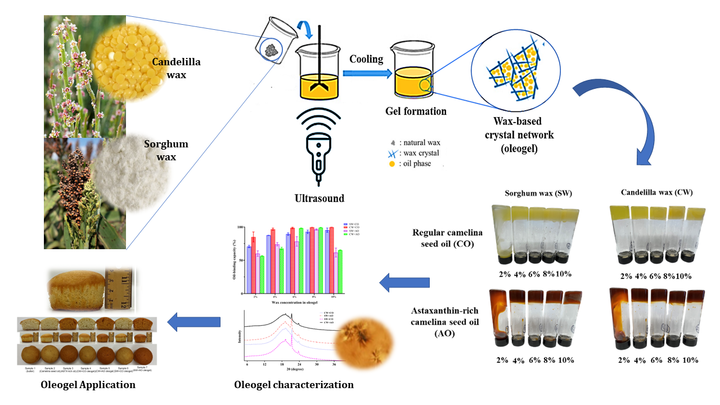

Development of fat replacers approaching: Oleogel formation

The growing concern about human health and its relationship with food brings different challenges for the food industry. Fats as the main macronutrient have been evaluated in the formulation of products to obtain excellent nutritional value without affecting the quality expected by the consumer. Thus, research has focused on fat replacers bringing different proposals and approaches.

The formation of oloeogels has been presented as an interesting solution, not only to trap lipid matrices but also to protect them and incorporate them into finished products. So far, the potential of these structures for the massive production and consumption industry is just beginning to be known.